Drilling solutions can be considered as an intricate mixture comprising of number of chemical additives which aid specific needs such as controlling the rheological properties and reducing corrosion. Inhibitors are substances that are added in small concentrations to corrosive environment to decrease the corrosion. Their applications can be found in drilling equipments. The effect of adding Zinc Sulphate and Carboxymethyl Cellulose to study their influence on the corrosion of carbon steel in Bentonite mud has been evaluated using Weight Loss Technique. This study focuses on determining rheological properties and corrosion characteristics. Results show CMC and ZnSO4 work as inhibitors when added to the Bentonite with inhibition

... Show More (3)

(3)

Hydrochloric acid (HCl) is a substance that is frequently utilized in industrial operations for important tasks such as chemical cleaning and pickling metallic surfaces.Therefore, the corrosion inhibition ability of three newly synthesized quinazoline derivatives namely, 3-allyl-2-(propylthio) quinazolin-4(3H)-one) (APQ), (3-allyl-2-(allylthio) quinazolin-4(3H)-one) (AAQ), (3-allyl- 2-( Prop -2-yn -1-ylthio) Quinazolin - 4 (3H) - one) (AYQ) were theoretically determined and these compounds were characterized using Fourier Transform Infra-Red (FTIR) and 1H and 13C Nuclear Magnetic Resonance (NMR) spectroscopic. A series of quantum chemical properties of these derivatives: EHOMO, ELUMO, energy gap (ΔE),dipole moment (μ), hardness (η), soft

... Show MoreThe inverse kinematics of redundant manipulators has infinite solutions by using conventional methods, so that, this work presents applicability of intelligent tool (artificial neural network ANN) for finding one desired solution from these solutions. The inverse analysis and trajectory planning of a three link redundant planar robot have been studied in this work using a proposed dual neural networks model (DNNM), which shows a predictable time decreasing in the training session. The effect of the number of the training sets on the DNNM output and the number of NN layers have been studied. Several trajectories have been implemented using point to point trajectory planning algorithm with DNNM and the result shows good accuracy of the end

... Show MoreAlO-doped ZnO nanocrystalline thin films from with nano crystallite size in the range (19-15 nm) were fabricated by pulsed laser deposition technique. The reduction of crystallite size by increasing of doping ratio shift the bandgap to IR region the optical band gap decreases in a consistent manner, from 3.21to 2.1 eV by increasing AlO doping ratio from 0 to 7wt% but then returns to grow up to 3.21 eV by a further increase the doping ratio. The bandgap increment obtained for 9% AlO dopant concentration can be clarified in terms of the Burstein–Moss effect whereas the aluminum donor atom increased the carrier's concentration which in turn shifts the Fermi level and widened the bandgap (blue-shift). The engineering of the bandgap by low

... Show More (1)

(1)

A friction stir spot welding (FSSW) process is an emerging solid state joining process in which the material that is being welded does not melt. In this investigation an attempt has been made to understand the effect of tool shoulder diameter on the mechanical properties of the joint. For this purpose four welding tools diameter (10,13, 16 and 19) mm at constant preheating time and plunging time were used to carry

out welding process. Effect of tool diameter on mechanical properties of welded joints was investigated using shear stress test and Microhardness of joint which welded was studied. Based on the stir welding experiments conducted in this study the results show that aluminum alloy (1200) can be welded using (FSSW) process with

(5)

(5)

In this paper investigate the influences of dissolved CO2/H2S gases, crude oil velocity and temperature on the rate of corrosion of crude oil transmission pipelines of Maysan oil fields southern Iraq. The Potentiostatic corrosion test technique was conducted into two types of carbon steel pipeline (materials API 5L X60 and API 5L X80). The computer software ECE electronic corrosion engineer was used to predict the influences of CO2 partial pressure, the composition of crude oil, flow velocity of crude oil and percentage of material elements of carbon steel on the rate of corrosion. As a result, the carbon steel API 5L X80 indicates good and appropriate resistance to corrosion compared to carbon steel API

... Show More (3)

(3)

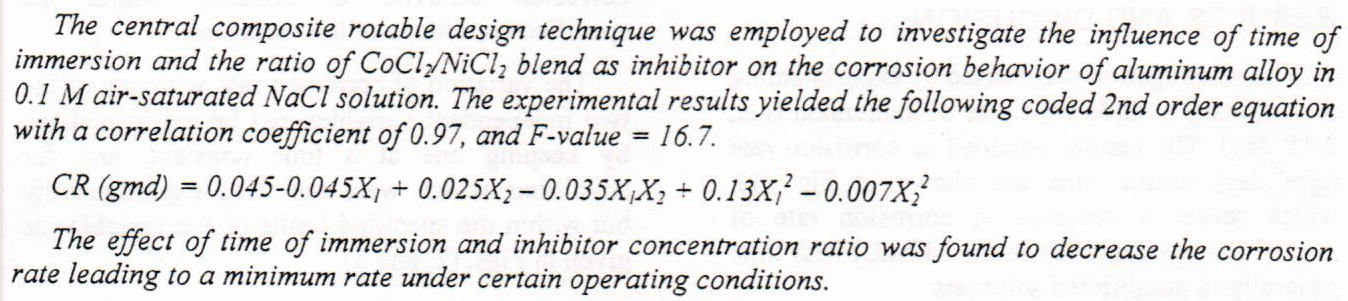

Abstract

This work involves studying corrosion resistance of AA 6061T6 butt welded joints using Two different welding processes, tungsten inert gas (TIG) and a solid state welding process known as friction stir welding, TIG welding process carried out by using Rolled sheet of thickness6mm to obtain a weld joint with dimension of (100, 50, 5) mm using ER4043 DE (Al Si5) as filler metal and argon as shielding gas, while Friction stir welding process carried out using CNC milling machine with a tool of rotational speed 1000 rpm and welding speed of 50mm/min to obtain the same butt joint dimensions. Also one of weld joint in the same dimensions subjected to synergistic weld

... Show More